Why Choose Hungerät as Your Industrial Submersible Pump Manufacturer

If you are responsible for a factory, a mine, or a large project site, you already know this: pump failures never happen at the right time. When a pump stops, production, drainage, or safety systems often stop with it.

That is why the choice of manufacturer matters.

- Proven Industry Experience: Hungerät has been involved in industrial pumping solutions for more than 25 years. This experience comes from real operating environments, not laboratory conditions.

- Broad Application Coverage: Whether your application involves clean water, wastewater, slurry, or chemical fluids, there are dedicated models designed for each type of medium.

- Built for Long-Term Operation: Industrial pumps are not short-term tools. Each unit is designed and tested with continuous operation, high load, and demanding site conditions in mind.

Choose by Fluid Type

WQ Series-Sea Water Sewage Pump

WQ Series-Sea Water Sewage Pump QY Series-Clean Water Submersible Pump

QY Series-Clean Water Submersible Pump GNWQ Series-Diry Water Sewage Pump With Cut

GNWQ Series-Diry Water Sewage Pump With Cut

Select by Material

WQ Series-Cast Iron Heavy Duty Sewage Pump

WQ Series-Cast Iron Heavy Duty Sewage Pump WQ Series-Stainless Steel Sewage Pump

WQ Series-Stainless Steel Sewage Pump WQ Series-Plastic Sewage Pump

WQ Series-Plastic Sewage Pump

Reliable Operation for Industrial Applications

In the industry, downtime is expensive. A blocked pump, an overheated motor, or a leaking seal can stop an entire system.

Industrial submersible pumps are widely used because they deliver stable performance where surface pumps struggle.

Drainage and circulation systems continue working without constant supervision.

Suitable for wastewater, sludge, and industrial effluents with varying solid content.

Pumps can be installed directly into existing pits, sumps, or drainage pipelines.

Fewer unexpected failures mean fewer emergency repairs and more predictable operating costs.

What Makes These Pumps Suitable for Industry

Industrial sites place constant mechanical and thermal stress on equipment. Industrial submersible pumps must be designed accordingly.

- Heavy-Duty Build: Thicker casings and reinforced components compared to standard commercial pumps.

- Designed for Continuous Operation: Suitable for long operating hours and 24/7 service when required.

- Wide Voltage Options: Options include 380V, 415V, 460V, and 660V to match industrial power systems.

- Built-In Protection: Sensors for leakage and overheating help reduce the risk of motor damage during operation.

Designed for Tough Working Conditions

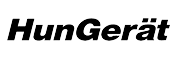

Factories, mines, and construction sites expose industrial submersible pumps to heat, moisture, vibration, and contaminated liquids.

- Efficient Motor Cooling: Keep stable performance during long operating cycles.

- Corrosion Resistance: Special coatings and materials reduce damage from chemicals and wastewater.

- Double Mechanical Seals: Reduce the risk of liquid entering the motor and prolong service life.

Options for Special Operating Conditions

Some projects operate beyond standard industrial conditions. For these cases, additional configurations are available for Hungerät industrial submersible pumps.

- Explosion-Proof Motors: Required for hazardous areas such as mines or oil and gas facilities.

- High-Temperature Cables: Suitable for pumping hot industrial wastewater, with temperatures up to 90°C.

- Agitators: Help disturb settled solids, allowing the pump to handle thicker sludge more effectively.

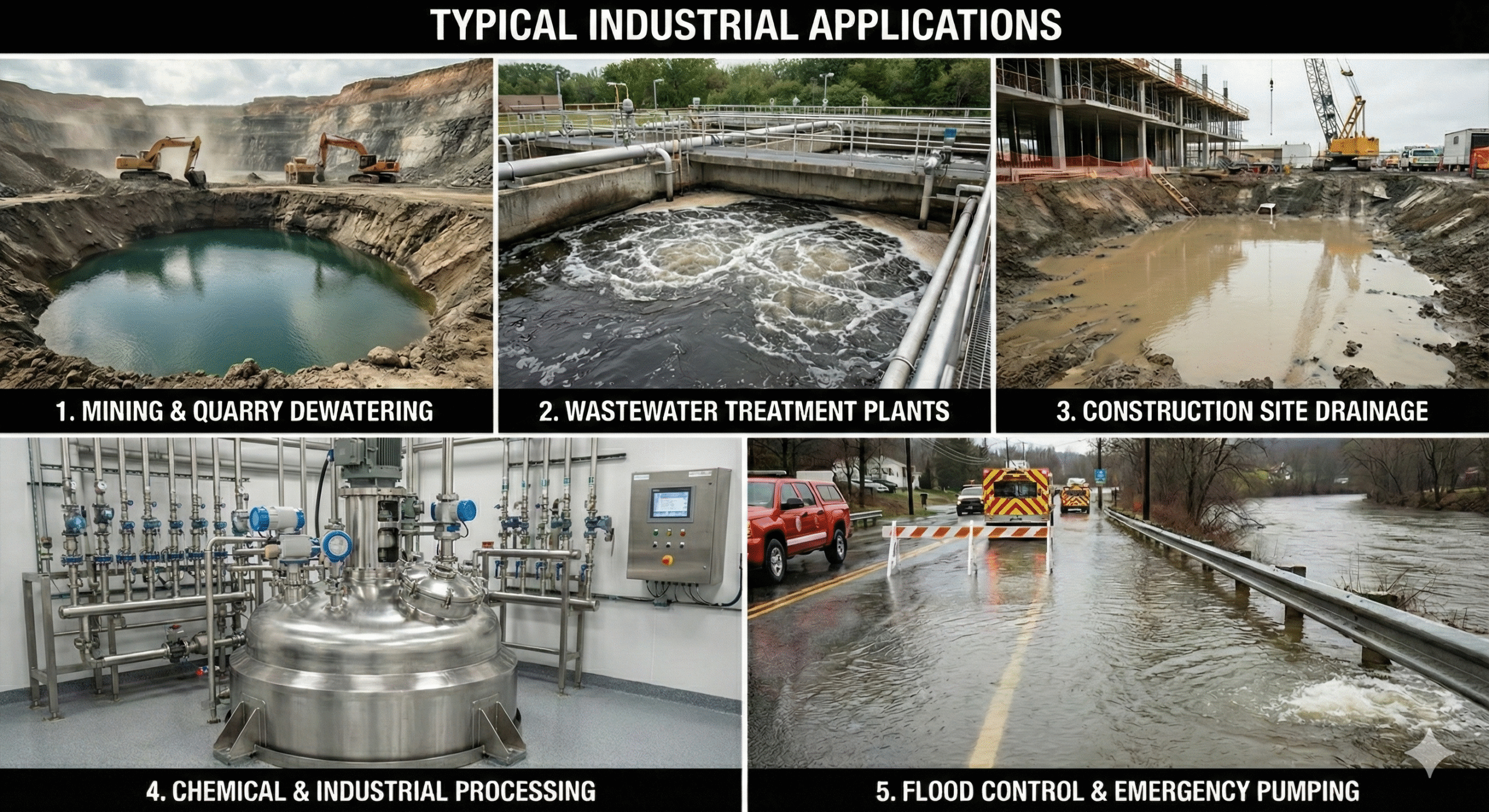

Typical Industrial Applications

Hungerät industrial submersible pumps are widely used in:

- Mining and quarry dewatering

- Wastewater treatment plants

- Construction site drainage

- Chemical and industrial processing

- Flood control and emergency pumping

Start by identifying the liquid type, required flow rate, and total head. Site conditions such as solids content, temperature, and explosion-proof requirements should also be considered. Hungerät engineers can assist in confirming the correct model.

Yes, when the appropriate impeller is selected. Vortex and cutter impellers are commonly used for sewage and trash, while slurry pumps are designed for sand and abrasive solids.

You should check the oil and seals every 2,000 to 3,000 operating hours. Routine maintenance helps reduce the risk of unplanned shutdowns.

Running a pump without water increases the risk of motor damage. In industrial applications, float switches or level sensors are often used to stop the pump automatically when water levels fall.